Hydrodynamic painting

of steel structures

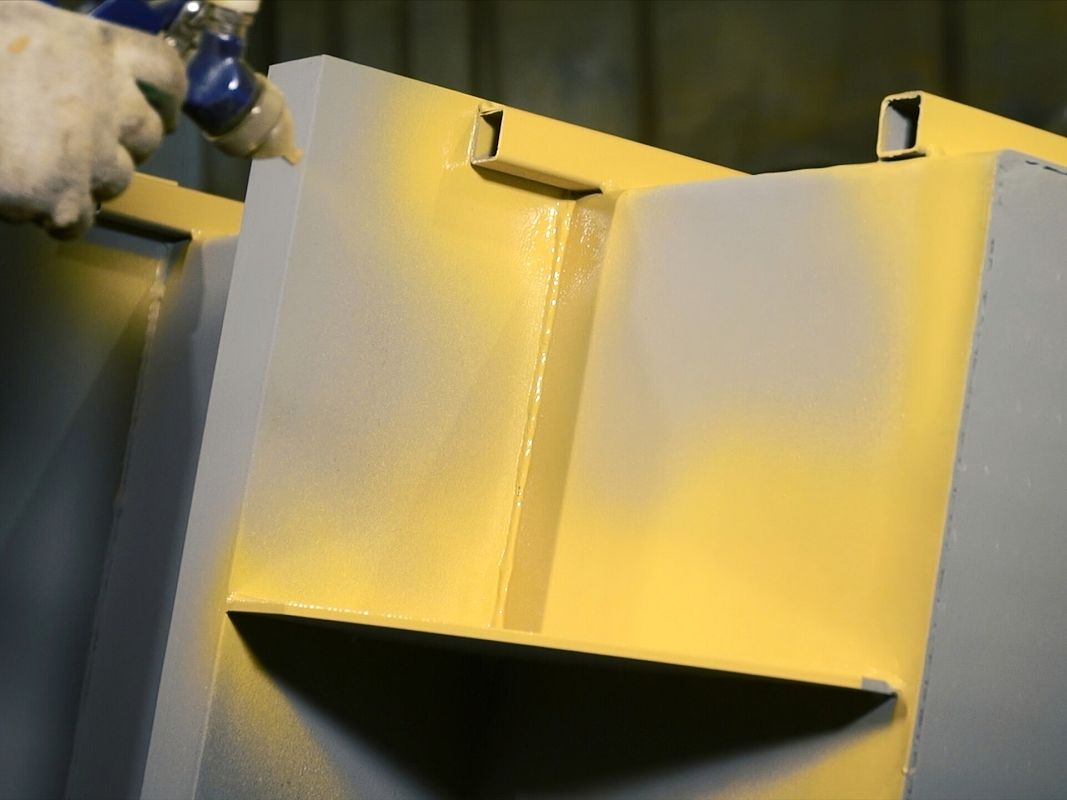

We are specialists in the field of protecting metal components against corrosion. We coat them with paints, adhering to rigorous quality standards and using modern materials and specialised tools. Among other methods, we use the wet painting technique, specifically hydrodynamic painting of steel structures. In this high-pressure technique, the paint does not come into contact with compressed air. As a result, a uniform protective layer is achieved, even when using very thick paint materials.

Wet painting technology

Wet painting technology is widely used in the industrial sector, allowing for effective protection of metal components operating in harsh environmental conditions. The advantages of using the hydrodynamic method include:

- The ability to achieve a thick protective coating while reducing paint consumption,

- Environmentally friendly (low dusting),

- Quick coverage of even very large steel structures with paint materials.

For more information about our offer – painting of steel structures – please feel free to contact our specialists.

Contact

Z.U.S.L. SPAW-MAL S.C.

ul. Krzywoustego 1, 84-300 Lębork

Exports: